If you’ve already validated your product idea and confirmed there’s a real market need, you’re likely now deep into product development. For sewn soft goods like backpacks, carrying cases, or medical garments, bringing your product to life takes more than just a solid concept. It takes a structured, realistic plan to move from prototype to full-scale production. This guide outlines the five key steps that take your idea from sketchpad to store shelves.

1. Finalize the Product Design

This step is where your initial concept becomes something that can be physically built. You may already have sketches or basic prototypes, but now is the time to refine every detail.

For sewn goods, that includes:

- Material selection (e.g., Cordura, mesh, webbing)

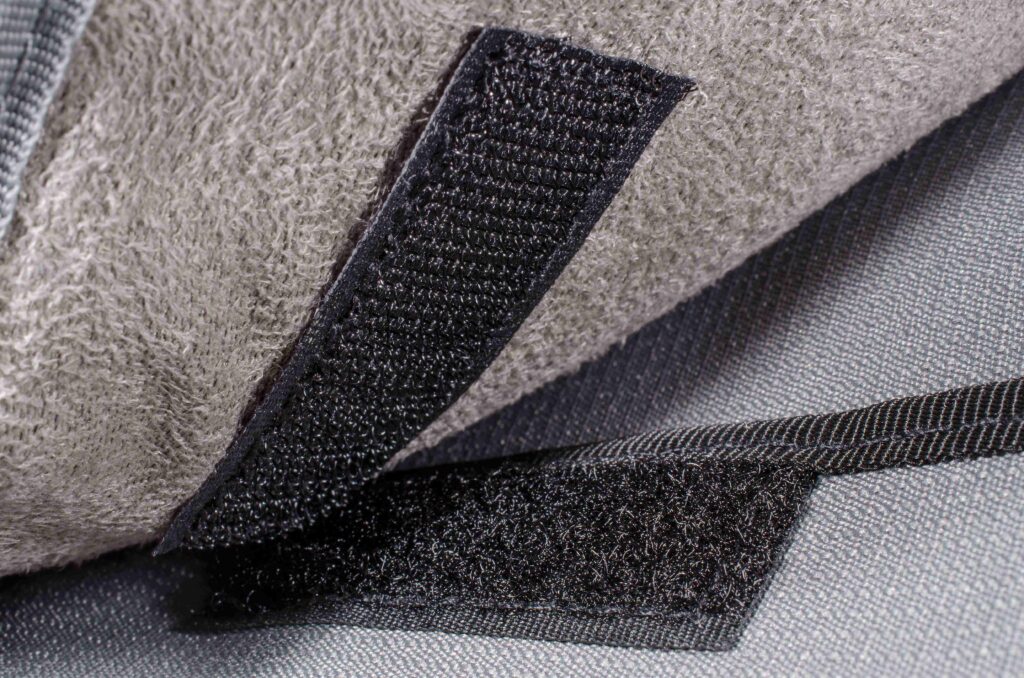

- Closure types (Velcro, zippers, buckles)

- Stitching types for durability

- Functional features like straps, pockets, and reinforcement zones

Let’s say you’re working on a better car seat travel bag for air travel. You’ll need to finalize design features like padded handles, extra-thick base panels, and secure zipper paths to ensure the seat is protected during baggage handling.

Working with a contract manufacturer early here can avoid costly redesigns later.

2. Prototype Like You Mean It

Prototyping is about turning your design files into something tangible. This is where you see how your product holds up to reality—and spoiler alert: it usually needs tweaks.

For example, one of our clients developed a first-aid kit for strollers that straps onto the handlebar or back of a car seat. The idea looked great on paper, but in real-world tests, the Velcro placement needed adjustment to prevent the bag from sagging.

Expect several rounds of prototyping to get it right. This phase may include:

- Initial sample construction

- Fit/function testing

- Cost reduction refinements

Your manufacturer should work with you on each revision. The more detailed and refined your prototype, the smoother the production process will be.

3. Field Testing: Like Sending Your Baby to College

You’ve watched your design grow up. Now it’s time to send it into the real world.

We often describe field testing as sending your baby off to college. You’ve done everything you can, but now the product has to perform without you. For soft goods, this means testing for:

- Daily use durability

- Comfort and ergonomics

- Real-world feedback from users in your target market

Back during the height of COVID, one inventive client prototyped a baby mask with a pacifier sewn into the center. The field tests revealed an issue with breathability—something not caught during initial prototype reviews. This kind of feedback can make or break a product’s success.

4. Prepare for Production: Plan Your Budget and Timeline

Real-World Spotlight: Board Game Bag Success Story

One great example of a well-executed launch came from a client we worked with nearly a decade ago. The product? A highly specialized carrying case for board games—not your average Monopoly box, but larger, heavier games in the Dungeons & Dragons genre. These were designed for enthusiasts who gather for hours-long game nights at friends’ homes.

They launched the product through a Kickstarter campaign and saw a tremendous response: over 250 preorders spanning five different color combinations. That early momentum gave them the funding to proceed with manufacturing, and they were able to take the project from prototype to fulfillment quickly by collaborating closely with our team.

This is a powerful example of how validation, niche targeting, and a clear plan for production can lead to a successful market debut.

Before scaling up, get real about the costs. Many entrepreneurs underestimate the expenses tied to:

- Materials sourcing

- Production minimums

- Tooling or pattern-making

- Quality assurance

A common roadblock? Running out of funding after final prototyping. Consider options like crowdfunding, early pre-orders, or even short-run production to raise the capital you need.

Keep your timeline flexible. Soft goods manufacturing often requires lead times for material availability, machine scheduling, and worker availability. At a domestic factory like ours, production lead times typically run 6–8 weeks. However, if you plan to manufacture overseas—especially in larger quantities—expect lead times of at least 3 months from the time you place your order.

5. Launch into Full-Scale Manufacturing

Once the design is finalized, the prototype is dialed in, and your product has passed field testing, it’s time to go big. Full-scale production is where your manufacturer takes over:

- Cutting and sewing according to approved patterns

- Assembling at scale

- Final inspections and packing

Look for a contract manufacturer who not only knows sewn products but offers prototyping, short-run production, and long-term manufacturing support under one roof. That way, your transition from design to market is seamless.

Developing a Simple Tech Pack for Your Manufacturer

A well-prepared tech pack is essential for communicating your vision clearly. It functions as the blueprint your manufacturer uses to understand the exact requirements of your product.

A basic tech pack should include:

- Flat sketches with front, back, and side views

- Final measurements and tolerances

- Materials and trim list (with sources, if available)

- Stitch and seam details

- Labeling and packaging instructions

- Photos of previous samples or prototypes

If you’re unsure where to start, check out our blog post on developing bag patterns to understand how detailed construction layouts influence patterning and manufacturing.

Pre-Production Checklist: Are You Ready to Manufacture?

Use the following table to double-check your manufacturing readiness:

| Item | Description | Complete? |

| Finalized Tech Pack | Includes sketches, materials, specs | ☐ |

| Approved Prototype | Functional and tested sample | ☐ |

| Material Sourcing | Reliable vendors identified | ☐ |

| Budget Plan | Costs for short and long runs calculated | ☐ |

| Production Partner Selected | Manufacturer aligned with your product | ☐ |

| Packaging & Labeling Plan | Barcodes, hang tags, inserts ready | ☐ |

| QA Plan | Criteria for final inspection | ☐ |

Want to Know How Much Weight Your Backpack Can Handle?

Another helpful resource: our blog post on how much weight a backpack can hold offers insight into how design decisions affect strength and longevity. This is especially useful if your product is performance-driven or targeting active users.

Whether you’re producing a baby gear innovation, a tactical bag, or a new kind of wearable, Fieldtex can guide you through every stage of sewn product development.

Request a quote or reach out to our team to learn how we can bring your product to market—with quality and efficiency you can count on.